Projects

Ultrasonic welding for food packaging

The high productivity of liquid or bulk materials requires a fast and economical process. Ultrasonic welding is therefore a good choice for many reasons. For example, beverage cartons or tubular bags can be sealed reliably, quickly, gently and tightly. At the same time, the process is cost-effective and environmentally friendly, as it does not require adhesives or other additives. The process is reliable and safe, as the sealing process is configured with just a few parameters and can be easily monitored. For an effective process for packaging, our 20 kHz ultrasonic components were used by the machine builder.

Cutting dough

For an effective cutting process of dough pieces, the company Aerne Engineering has developed a robot cell. The dough pieces are detected by a Sendor on the conveyor belt and then cut according to customer specifications by a total of four 6-axis robots with ultrasonic knife units supplied by us.

Cutting wrap

Together with a Belgian machine builder, we were able to manufacture an automatic system for cutting wraps using ultrasonic. The synchronized cutting ensures a clean cut of the filled wraps.

This food cutting machine uses a Boa series generator with a working frequency of 20 kHz and a converter type: HCV2010 with a titanium sonotrode.

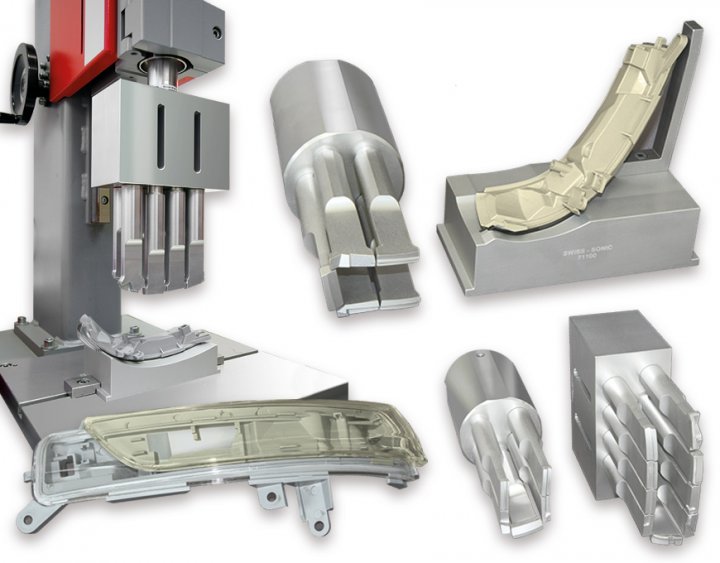

Car indicator

Nice designed components are not always easy for further processing. This depicted object is an indicator for vehicles.

The requirements for the welding connection were clear. It should be absolutely waterproof without any marks. Due to the construction of the parts our specialists were challenged to find a convenient solution.

After intensive studies we concluded it is only possible if we weld the object twice. It was not easy to achieve a sealed result. With our composite sonotrodes we were able to attain an equalamplitude. A constant welding result has been ensured.

The sonotrodes as well as the fixture were made with modern machine tools. The surfaces were milled with 3-D technology.

On the enclosed image you can see the result of the indicator which were welded in two steps.

Cutting cheese

Our ultrasonic devices are usable for various tasks. It can for example be used in the food sector. In cooperation with a mechanical engineer the installation of a unit could be realized, which cuts cheese with a titanium sonotrode.

Our range of products includes small cheese dairy up to large equipments.

In this project we have used our generator type: Viper as well as components in compliance with the health and hygiene standards.